- Inspection & Maintenance

- HSE Ladder, Steps, Walkways & Access Equipment Inspection

- Ladder Inspection - Fixed Ladder, Temporary Ladder & Ladder Tie Inspection

Ladder Inspection - Fixed Ladder, Temporary Ladder & Ladder Tie Inspection

Fixed and Temporary Ladders are commonly used in the workplace and as such fall under the Provision and Use of Work Equipment Regulations (PUWER) 1998.

The PUWER Regulations require the duty holder to ensure that any work equipment provided is:

Suitable for use, and for the purpose and conditions in which it is used

Maintained in a safe condition for use so that people's Health and Safety are not at risk; and

Inspected in certain circumstances to ensure that it is, and continues to be safe for use.

It is the duty holder’s responsibility to ensure that before use, the equipment provided is inspected by a competent person.

All ladder users must follow the pre-use inspection procedure.

Generally formed from steel or aluminium they provide access to places of work, both internally and externally, such as roof tops, plants, silos, and the like. Wherever they are located, it is vital to ensure the safety of workers who use them.

Our role when inspecting your site's ladders is to report our findings in light of current recommendations of good practice. For this, we work to the British Standards:

BS 4211:2005+A1:2008 – Specification for permanently fixed ladders.

BS 5395-3:1985 – Code of Practice for the design of industrial-type stairs, permanent ladders, and walkways.

BS EN 14122 – Safety of machinery. Permanent means of access to machinery. Working platforms and walkways.

BS 4211:2005+A1:2008 – Specification for permanently fixed ladders. BS 5395-3:1985 – Code of Practice for the design of industrial-type stairs, permanent ladders, and walkways. BS EN 14122 – Safety of machinery. Permanent means of access to machinery. Working platforms and walkways.

As part of the process, our engineers inspect ladders, ensuring the installation is compliant with current legislation, and checking for items that may present an obvious hazard, such as slips, trips, falls, impact damage, etc.

They will also check that all fixings are secure and that all moving parts operate correctly, for example, self-closing gates at the head of a ladder. We then allocate each item a unique reference number, tag the item identifying the next inspection due date, and prepare a report for the customer on our findings. This provides customers with complete peace of mind that their ladders are fully compliant and that safety is being maximised.

Our Temporary Ladder Inspection service is carried out by Ladder Association trained engineers. We inspect the ladders in accordance with manufacturer's recommendations and following Ladder Association guidelines.

Temporary ladders should only be used for short-duration tasks (as a guide, if your task would require staying up a leaning ladder or stepladder for more than 30 minutes at a time, it is recommended that you consider alternative equipment) and providing a risk assessment has been carried out showing that equipment offering a higher level of fall protection is not justified because of the low risk and short duration of use; or there are existing workplace features which cannot be altered.

The main regulations covering temporary ladders are the Provision and Use of Work Equipment Regulations (PUWER) 1998 & The Working at Height Regulations (WAHR) 2005, however many others are applicable. The WAHR spells out the need to check and maintain ladders and clearly states the general requirements of PUWER to maintain and inspect work equipment annually or more frequently depending on use. (Regulations 5 and 6 (2)).

The British standards that apply to temporary ladders are:

BS 1129 Specification for portable timber ladders, steps, trestles, and lightweight stagings British Standards Institution

BS 2037 Specification for portable aluminium ladders, steps, trestles, and lightweight stagings British Standards Institution

BS EN 131 Ladders (Specification for terms, types, functional sizes; Specification for requirements, testing, marking; User instructions; Single or multiple hinge-joint ladders) British Standards Institution

We undertake the inspection of Soll GlideLoc Y-Spar Ladders in accordance with BS EN 353-1:2014 & PUWER regulations and manufacturer's instructions.

The Soll GlideLock systems we inspect can be found across a wide range of industries including Telecommunications, Utilities, Wind, Chimneys, and general buildings. Where they are used on ladders – both retro-fitted to traditional ladders comprising a pair of stringers/stiles joined with rungs and on Y-spar style ladders. The ladders are inspected in accordance with PUWER regulations whilst the fall protection system is in accordance with EN 353-1:2014.

We provide a Compliance based inspection & testing service as part of a Periodic Inspection regime / PPM for GlideLoc Y-Spar ladders as we realise that the safety of your fixed ladders & their integral fall protection equipment is imperative in creating a safe working environment.

PUWER regulation 6 specifies the circumstances where inspection is required to ensure healthy and safe conditions are maintained: one circumstance identified is… where work equipment is exposed to conditions causing deterioration liable to result in dangerous situations. Given Glideloc Y-Spar ladders are often located external to a building or at height – they often require a regular planned inspection.

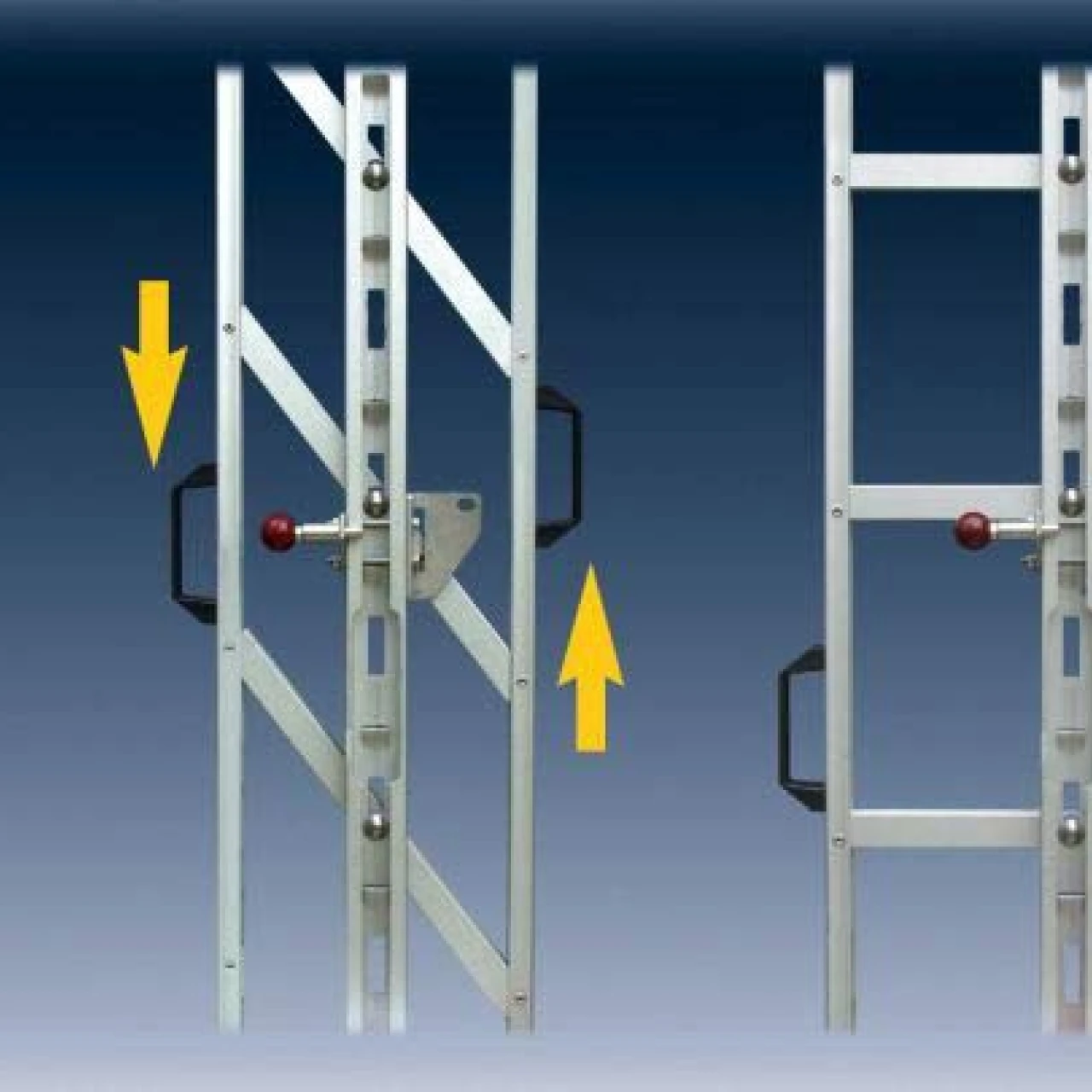

The PivotLoc ladders are inspected in accordance with PUWER regulations whilst the fall protection system is in accordance with EN 353-1:2014.

We offer a compliance-based inspection & testing service as part of a Periodic Inspection regime / PPM for PivotLoc ladders. The safety of your ladders & their associated fall protection equipment is imperative in creating a safe working environment. Our PivotLock ladder inspection service is integral in creating this environment.

PUWER regulation 6 specifies the circumstances where inspection is required to ensure healthy and safe conditions are maintained: one circumstance identified is… where work equipment is exposed to conditions causing deterioration liable to result in dangerous situations. Given the PivotLoc ladders are often located external to a building or at height – they often require a regular planned inspection.

Ladder restraint ties are a critical piece of worker safety equipment and as such are covered under the umbrella legislation of the Provision and Use of Work Equipment Regulations 1998 (PUWER) and BS EN 8539. Following the guidelines of PUWER, our engineers inspect ladder restraint ties in accordance with the manufacturers’ recommendations. This includes a regular visual inspection, combined with a physical pull test to determine the suitability of fixing.

Ladder restraint ties are typically installed discreetly adjacent to or beneath windows on the outside of buildings. When used in conjunction with a ratchet strap to restrain the ladder they provide a safe means of securing a ladder for short-duration window cleaning tasks. As the ladder tie is put under tension by the restraint strap, it is important to ensure that it is fit for purpose and will not pull out whilst the operative ascends the ladder. Our regular inspection and testing will proof-load the ladder tie to check its suitability.

Ladder re-certification time schedule

| Fixed Ladder | every 12 months |

|---|---|

| Temporary Ladder | every 12 months |

| Y-Spar Ladder | every 12 months |

| PivotLoc Ladder | every 12 months |

| Ladder Tie | every 12 months |

Request free quotation

Fill in the form below to request your free, no-obligation ladder or ladder tie inspection quotation.